Why 30% of Packaged Food Never Reaches a Consumer

AUTHOR

Srivatsan Kadambi Seshadri & Thilak Satya Sree

Thirty percent of packaged food never makes it to a consumer's mouth.

Not because of recalls or contamination. Because of expiry dates, damaged shipments, and overproduction. The math is brutal: the F&B industry loses more than $100 billion annually to waste across manufacturing, distribution, and retail.

With rising input costs and razor-thin margins, these losses aren't just wasteful, they're existential. So what's actually being done about it?

Where the Waste Actually Happens

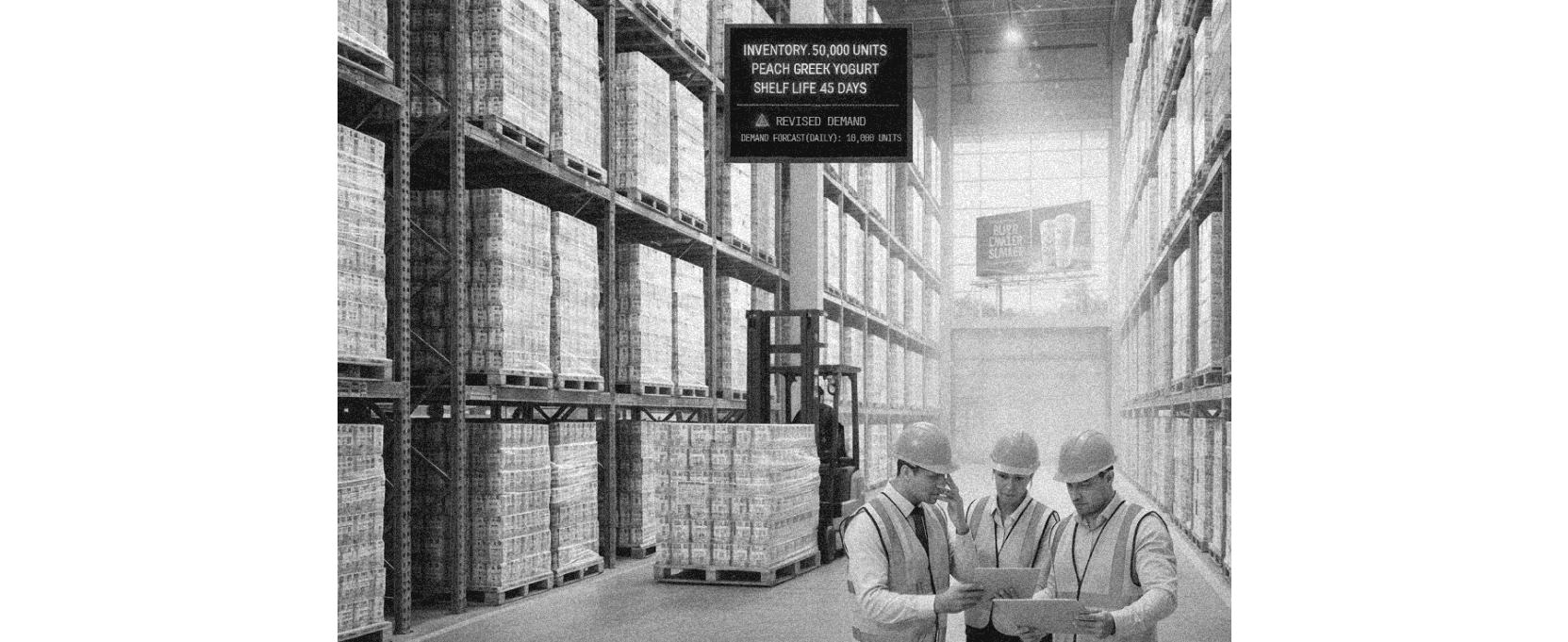

Picture a regional distribution center for a national yogurt brand. You've got 50,000 units of peach greek yogurt sitting in inventory, each with a 45-day shelf life. Your demand forecast says you'll move 40,000 units this month.

Sounds fine, right?

Except the forecast is based on last month's data and doesn't account for the unexpected heatwave hitting your primary markets, the competitor promotion that just launched, or the fact that three of your retail partners are running their own conflicting promotions next week.

By the time you realize demand is actually 35,000 units, you've got 15,000 units with 10 days left until expiry. You can try emergency transfers to other regions, markdown the price, or eat the write-off.

This scenario plays out thousands of times across the industry. The pattern is always the same: inaccurate forecasts lead to overproduction, static inventory policies don't account for perishability, poor visibility means you find out too late, and disconnected systems can't adapt fast enough.

The result? Waste that didn't need to happen.

"Thirty percent of packaged food never makes it to a consumer. That's not an execution problem, that's a planning problem."

The Shift From Reactive to Proactive

Progressive F&B companies aren't just buying better software. They're changing how they think about waste, treating it as a signal that something in their planning process is broken.

They're investing in capabilities that help them intervene before products expire:

Smarter forecasting that uses AI (more powerful math) to account for weather, events, promotions, and digital signals

Demand sensing that detects shifts in real-time, so you can adjust production this week instead of next month

Inventory optimization that factors in shelf life and perishability, not just reorder points

End-to-end visibility that flags at-risk inventory before it's too late

Inventory rebalancing that shifts stock from surplus to deficit zones

Supply drawdown simulations that reveal future demand windows where you can safely consume aging stock

The companies doing this well aren't just reducing waste. They're fundamentally changing the health of their operations:

15-30% reduction in forecast error

10-20% decrease in expired inventory write-offs

5-12% improvement in freshness-adjusted fill rates

5-10% lower inventory holding costs

These aren't marginal improvements. They're game-changers.

How Lyric Studio Enables This

At Lyric, we built our platform specifically for these kinds of problems—where you need to move fast, account for complexity, and connect decisions across forecasting, inventory, and execution.

Stop Overproducing in the First Place

Our forecasting capabilities allow you to adapt to seasonality, promotions, weather patterns, and local events to generate accurate SKU-location forecasts—even in volatile categories like fresh produce or seasonal beverages.

Translation: You produce closer to what you'll actually sell, which means less waste from the start.

Respond to What's Happening Right Now

Traditional monthly forecasts are dead on arrival. By the time you've finalized the numbers, the market has already shifted.

Lyric's demand sensing capabilities capture real-time signals: POS data, digital engagement, regional events, weather disruptions, and adjust predictions accordingly. When festival demand spikes or a heatwave hits, you know within hours, not weeks.

To offer an example, a beverage company using Lyric detected an unexpected surge in demand for sports drinks during an early-season heatwave and increased production allocation by 20% within 48 hours. They captured the demand spike without emergency shipments or stockouts.

Optimize Inventory With Shelf Life in Mind

Most inventory systems treat a can of soup the same as a carton of milk. Lyric Studio enables differentiation. Our optimization engines adjust safety stock, replenishment policies, and deployment strategies based on perishability; accounting for transit time, freshness requirements, and regional consumption patterns. You can even use Machine Learning (ML) models to predict shelf-life obsolescence and adjust inventory recommendations proactively.

See Problems Before They Become Write-Offs

Lyric Studio also provides the ability for live visibility into inventory across DCs, retail locations, and in-transit shipments. It flags SKUs nearing expiry, aging inventory, and at-risk stock, so you can act before you're stuck with an unsellable product.

What can you do with that information? Remember those 15,000 units of peach greek yogurt, Lyric Studio would have flagged the risk 30 days earlier, offering a choice of decisions: transfer stock from surplus to deficit zones, run targeted promotions or markdowns, adjust production schedules to draw down aging inventory, or simulate different scenarios to find the least-bad option.

"The difference is moving from 'we have a waste problem' to 'we have options to prevent waste before it happens."

Balance Inventory and Plan for Drawdown

Using Lyric's Deployment Planning engine, we generate transfer recommendations that balance inventory levels across locations while weighing trade-offs: logistics cost vs. salvage risk vs. service level targets.

Lyric Studio also runs simulations to detect future periods where accumulated supply can be safely drawn down, based on forecasted demand, expiry windows, and production constraints. Instead of discovering you have a problem when inventory hits critical age, you're planning weeks ahead for how to consume it.

Built for How Supply Chains Actually Work

Unlike rigid, one-size-fits-all tools, Lyric Studio is composable. You can use the full platform or deploy individual modules based on what you need right now. Lyric Studio handles messy data from any system, runs multiple what-if scenarios concurrently, and adapts to category differences - whether you're dealing with fresh produce, dairy, beverages, or packaged goods.

Whether you're running local operations or a global network, Lyric Studio scales with you.

The Bottom Line

"Waste reduction isn't a back-office initiative anymore. It's a board-level strategy."

Here's the thing: waste reduction isn't just about sustainability or corporate responsibility anymore. With margins under pressure and input costs rising, it's about survival.

The companies winning this battle aren't the ones with the best intentions. They're the ones with the best intelligence; systems that help them see problems coming, test options quickly, and act before waste happens.

Lyric Studio was built to be that system. If you're ready to move from reactive firefighting to proactive waste prevention, let's talk.

Read more

The Innovation Tax: Why Your Best Work Doesn't Compound

Feb 18, 2026

Brittany Elder

read more

What Sudoku Teaches Us About Enterprise Software

Feb 17, 2026

Akshat Jain

read more

Taming the Toughest Problems in Transportation

Dec 18, 2025

Amit Hooda & Priyesh Kumar

read more

How to Plan When Nothing Goes According to Plan

Dec 15, 2025

Dr. Nilendra Singh Pawar

read more

Why We Fall Back to Heuristics

Nov 24, 2025

Frank Corrigan

read more

What You Group is What You See

Nov 3, 2025

Frank Corrigan

read more

The Cost of Curiosity

Sep 24, 2025

Brooke Collins

read more

Lyric Named a 2025 Gartner® Cool Vendor in Cross-Functional Supply Chain Technology

Sep 2, 2025

Sara Hoormann

read more

Built for Builders. Backed to Scale.

Aug 5, 2025

Ganesh Ramakrishna

read more

Generative AI meets Time Series Forecasting

May 2, 2025

Deb Mohanty

read more

The Dying Art of Supply Chain Modeling

Apr 15, 2025

Milind Kanetkar

read more

Tariffs, Trade Wars, and the AI Advantage: Why Fast Modeling Wins

Apr 7, 2025

Lyric Team | Prime Contributors - Laura Carpenter, Victoria Richmond, Saurav Sahay

read more

Lyric Leverages NVIDIA cuOpt to Elevate Supply Chain AI

Mar 18, 2025

Sara Hoormann

read more

The Technology Behind Modeling at Scale

Mar 14, 2025

Ganesh Ramakrishna

read more

Our Dream is to Make Every Supply Chain AI-First

Oct 18, 2023

Ganesh Ramakrishna

read more

What Is a Feature Store Anyway?

Mar 14, 2024

Sara Hoormann

read more

Supply Chain AI Ain’t Easy

Feb 20, 2023

Ganesh Ramakrishna & Sara Hoormann

read more

Four Ways to Improve Supply Chain Operations with Machine Learning

Jan 26, 2023

Vish Oza

read more

Prediction is the New Visualization

May 30, 2024

Frank Corrigan

read more